Why You Should Use Drones for Volumetric Surveys

Without the right information, keeping your project running on-time and on-budget is impossible.

Professionals across a wide range of industries, from construction to logistics, rely on volumetric surveys for this precious data.

So, what are these surveys good for? They’re used to calculate the volume of earthworks, stockpiles of materials, and keep operations flowing smoothly.

For a number of reasons, understanding the volume of materials in a given area is crucial for planners and managers. It helps determine burn rates, current supply levels, the value of materials on-site, and much more.

Without this information, operations run the risk of grinding to a halt from supply shortages.

Until recently, these surveys were either inaccurate, too expensive, or took too long to maximize their use. But now, there’s a better way.

Volumetric Surveys of the Past

Traditionally, conducting volumetric surveys usually required the use of both survey teams and some mathematical gymnastics. Though the process is relatively straightforward, it’s also expensive and time-consuming.

To illustrate traditional methods better, let’s look at a construction site that needs to know how much gravel remains in a gravel pit. For this example, let’s assume both low-tech and high-tech options are available.

In the low-tech version (see video above), tools such as a distance measuring wheel, level, and measuring tape are used to find the volume of the cone and the volume of the center prism which make up the pile. This method not only takes a lot of time, but also leaves plenty of room for errors – producing inaccurate results.

In reality, it’s only slightly better than simply “eyeballing” the gravel pile.

The traditional high-tech method employs a survey team. Although this yields an accurate result, it too, takes a long time – and is expensive.

These teams use tools such as theodolites, analyzing the collected measurements offsite, later offering their report to the client.

In some cases, it can take weeks for the report to reach the customer. And to top it off, it could cost thousands of dollars for a single survey.

There’s got to be a better way, right? There is.

The Modern Solution

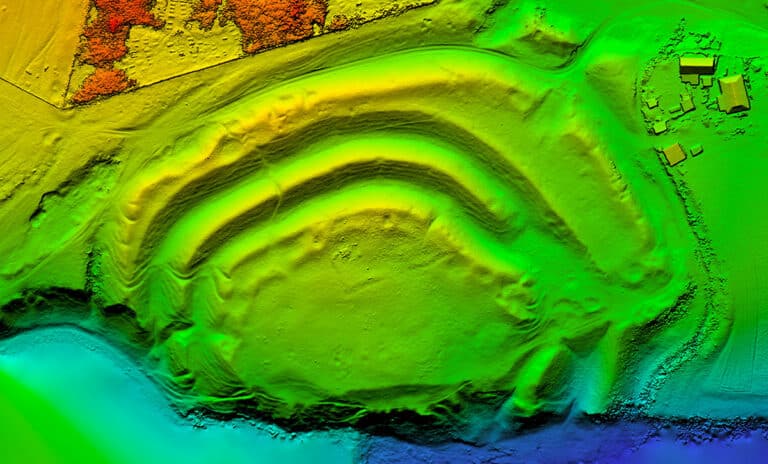

Today, drones offer a unique and proven solution. UAV technology provides real-time volumetric calculations of stockpiles at a fraction of the cost and time of traditional methods.

Many operations are already using drones for this and enjoying the rewards of the technology.

One of the most important benefits? Speed.

A commercial drone pilots complete volumetric surveys in almost no time at all.

Even with inexpensive drones – many of which cost less than hiring a survey team – calculations can be completed in a matter of minutes.

With one of many software options on the market, such as DroneDeploy or Pix4D, the pilot simply selects a pile of materials for the drone to analyze. A flight plan is automatically generated, and the drone is launched.

After a few minutes of flying, the drone returns to the launch point and the information is processed. It’s that simple.

Additional Benefits

As if saving time and money wasn’t enough, the benefits of this modern solution don’t end there.

Drones allow for stockpile volumes to be calculated without causing work stoppages around the material in question.

When using a survey team, work around the pile must cease for safety reasons. Heavy equipment, for example, must operate outside the immediate area where the survey team is working.

Delays caused by these stoppages significantly impact the completion of work, potentially causing your project to fall behind schedule. With drones, work continues uninterrupted.

In addition to an improved workflow, better supply chain management is also possible.

Imagine you need to know the remaining supply of soil on-site, and you’re waiting for a survey team to complete their report. The delay between when the data was taken and the report hitting your hands means that the volume may already have changed.

With a possible lag time of weeks before getting the information you need, the data can already be too old to act on.

On the other hand, drones can be flown several times a day, providing you with real-time calculations of the materials on hand. Suppliers can be notified far in advance, long before running out of materials.

Importantly, you ensure your sites don’t fall victim to running out of crucial resources.

Bringing It All Together

Most of the challenges associated with volumetric surveys are either eliminated or significantly reduced by adopting drone technology. From highly accurate results, to the speed of completion, drones truly streamline the entire process.

Managers will appreciate the reduction in cost and time to complete their job. Personnel on-site will benefit from better supply chain management.

And with less downtime from intrusive survey teams, everyone wins.

With drones, it’s simply a better way.

So, which drone is right for you? And, how do you get started? Do you hire out or bring your drone program in-house?

At Consortiq, we help you find a better way with drones, from consultation and program implementation to actually doing the work for you.

Ready to learn more? Just complete the form below to schedule a risk-free consultation!

David Daly - Contributing Author

David Daly, is an award-winning photographer/writer and licensed (FAA) Commercial sUAS pilot. A graduate of the United States Naval Academy, David is a former Marine Corps officer with a BS in Oceanography and has earned his MBA from the University of Redlands. David has worked for Fortune 100 companies and has a background in aerospace, construction, military/defense, real estate, and technology.